AIR CYCLONE BLADES

PROBLEM

The air cyclone blades and the interior of the units at this Owens Corning manufacturing facility had corroded over time to the point that they were losing their structural integrity. These high velocity cyclone collectors remove particulates from in-plant air. Dirty air enters the cyclone and centrifugal force moves the particulates against the cone wall, out of the airstream and into a storage unit. The deterioration was enough that the air cyclone units had to be taken out of service periodically for repairs, which impacted the manufacturing process and was costly.

The facility had four new air cyclone units built, but needed to find a way to protect the blades and interiors of the units from corrosion and abrasion and extend their service life.

SOLUTION

Owens Corning turned to Southern Industrial Linings, a Rhino Linings® applicator, to recommend a coating for the job. Southern Industrial Linings chose Rhino Extreme HP 11-50. Its high tensile, tear and elongation properties give the coating excellent abrasion and impact resistance, key properties for this application.

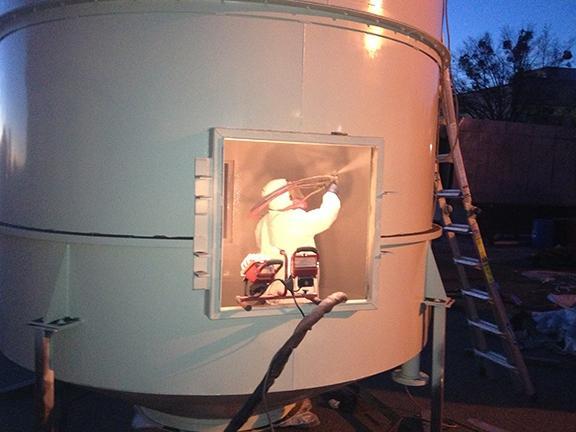

First, the applicator abrasive blasted the entire surface of the blades and the interior of the units to a 4 mil profile. Next the units were cleaned and dried to prepare the surface for the coating. Finally, 100 mils (2.5 mm) of Rhino Extreme HP 11-50 was spray-applied to the blades and interiors using high pressure plural component spray equipment.

Conditions at the time of installation were challenging. The weather was extremely cold in Georgia and the work was being done outside. But because Rhino Extreme HP 11-50 is a pure polyurea lining system, it has a robust application window with the ability to spray at low temperatures and high humidity. While it was tough on the applicators, the coating applied easily even in less-than-ideal conditions.

RESULTS

The entire job was completed by the applicator in two 18-hour days. The air cyclone units are fully operational, and the manufacturer is happy with both the look and the performance of the coating. There has been no downtime needed for repairs since the coating was installed.